-

$2.25

$2.25 -

$3.25

$3.25 -

$4.25

$4.25 -

$2.25

$2.25 -

$3.25

$3.25 -

$4.25

$4.25 -

$2.25

$2.25 -

$3.25

$3.25 -

$4.25

$4.25 -

$2.25

$2.25 -

$3.25

$3.25 -

$4.25

$4.25 -

$2.00

$2.00 -

$2.00

$2.00 -

$3.00

$3.00 -

$4.00

$4.00 -

$2.00

$2.00 -

$2.00

$2.00 -

$3.00

$3.00 -

$4.00

$4.00 -

1 x DIN 17175 ST35.8$1.00

1 x DIN 17175 ST35.8$1.00 -

$1.25

$1.25 -

$1.25

$1.25 -

$1.25

$1.25 -

$1.25

$1.25 -

$1.25

$1.25 -

$1.25

$1.25 -

$1.25

$1.25 -

$1.25

$1.25

No products

Product successfully added to your shopping cart

There are 29 items in your cart. There is 1 item in your cart.

Categories

-

Carbon Steel Pipes & Tubes

- ASTM A106 SA106 Pipe

- ASTM A53 SA53 Pipe

- ASTM A135 SA135 Pipe

- ASTM A139 SA139 Pipe

- ASTM A179 SA179 Tubes

- ASTM A210 SA210 Tubes

- ASTM A333 SA333 Pipe

- ASTM A334 SA334 Pipe

- ASTM A500 SA500 Pipe

- ASTM A501 SA501 Pipe

- ASTM A512 SA512 Tube

- ASTM A513 SA513 Tube

- ASTM A517 SA517 Tube

- ASTM A519 SA519 Tube

- ASTM A671 SA671 Pipe

- ASTM A672 SA672 Pipe

- ASTM A252 Steel piling pipe

- Carbon Steel Seamless Pipe

- Carbon Steel Pipe Japan

- Carbon Steel Pipes Europe

- Carbon Steel Pipe China

-

Stainless Steel Pipes & Tubes

- Stainless Steel Tube, Tubing & Pipe

- ASTM A271 ASME SA271 Pipes/ Tubes

- ASTM A312 ASME SA312 Pipes/ Tubes

- ASTM A358 ASME SA358 Pipes/ Tubes

- ASTM A376 ASME SA376 Pipes/ Tubes

- ASTM A409 ASME SA409 Pipes/ Tubes

- ASTM A430 ASME SA430 Pipes/ Tubes

- ASTM A632 ASME SA632 Pipes/ Tubes

- ASTM A778 ASME SA778 Pipes/ Tubes

- ASTM A813 ASME SA813 Pipes/ Tubes

- ASTM A814 ASME SA814 Pipes/ Tubes

- ASTM A826 ASME SA826 Pipes/ Tubes

- ASTM A851 ASME SA851 Pipes/ Tubes

- ASTM A213 ASME SA213 Pipes/ Tubes

- ASTM A249 ASME SA249 Pipes/ Tubes

- ASTM A268 ASME SA268 Pipes/ Tubes

- ASTM A269 ASME SA269 Pipes/ Tubes

- ASTM A270 ASME SA270 Pipes/ Tubes

- ASTM A511 ASME SA511 Pipes/ Tubes

- ASTM A688 ASME SA688 Pipes/ Tubes

-

Alloy Steel Pipes & Tubes

-

Alloy Steel Tubes

- ASTM A213 T1 Alloy Steel Tube

- ASTM A213 T2 Alloy Steel Tube

- ASTM A213 T5 Alloy Steel Tube

- ASTM A213 T5b Alloy Steel Tube

- ASTM A213 T5c Alloy Steel Tube

- ASTM A213 T9 Alloy Steel Tube

- ASTM A213 T11 Alloy Steel Tube manufacturer and suppliers

- ASTM A213 T12 Alloy Steel Tube

- ASTM A213 T17 Alloy Steel Tube

- ASTM A213 T21 Alloy Steel Tube

- ASTM A213 T22 Alloy Steel Tube

- ASTM A213 T23 Alloy Steel Tube

- ASTM A213 T24 Alloy Steel Tube

- ASTM A213 T36 Alloy Steel Tube

- ASTM A213 T91 Alloy Steel Tube

- ASTM A213 T92 Alloy Steel Tube

- ASTM A213 T122 Alloy Steel Tube

- ASTM A213 T911 Alloy Steel Tube

- ASTM A513 Grade 8620 Alloy Steel Tube

- ASTM A513 Grade 4130 Alloy Steel Tube

- ASTM A513 Grade 4118 Alloy Steel Tube

- ASTM A513 Grade 4140 Alloy Steel Tube

- ASTM A513 Grade 8630 Alloy Steel Tube

-

Alloy Steel Pipes

- ASTM A335 P1 Alloy Steel Pipe

- ASTM A335 P2 Alloy Steel Pipe

- ASTM A335 P5 Alloy Steel Pipe

- ASTM A335 P5b Alloy Steel Pipe

- ASTM A335 P5c Alloy Steel Pipe

- ASTM A335 P9 Alloy Steel Pipe

- ASTM A335 P11 Alloy Steel Pipe Manufacturer & Suppliers

- ASTM A335 P12 Alloy Steel Pipe

- ASTM A335 P15 Alloy Steel Pipe

- ASTM A335 P21 Alloy Steel Pipe

- ASTM A335 P22 Alloy Steel Pipe Manufacturer and suppliers

- ASTM A335 P23 Alloy Steel Pipe

- ASTM A335 P24 Alloy Steel Pipe

- ASTM A335 P36 Alloy Steel Pipe

- ASTM A335 P91 Alloy Steel Pipe

- ASTM A335 P92 Alloy Steel Pipe

- ASTM A335 P122 Alloy Steel Pipe

- ASTM A335 P911 Alloy Steel Pipe

- Alloy Steel Pipe & Tube Specification

-

Alloy Steel Tubes

- Special Steel Grades Pipes & Tubes

- API 5L Pipe

- Titanium Pipes & Tubes

- Welded/ ERW Pipes

- Mild Steel Pipes & Tubes

- Ductile Iron Spun Pipe & Ductile Iron Flanged Pipe Cast

- Capillary Tube| Capillary Tubing

- Boiler Tube

- Heat exchanger tubes

- Cupro Nickel Tube

- Aluminium Tube

- Corten Steel Pipes & Tubes

- EIL Approved Pipes

- IBR Pipe/ Tube & Non IBR Pipe/ Tube

- Black Pipes

- Galvanised Steel Pipes/ GI Tubes

- SS Coiled Tubing/ Tubes

- SS Electropolished Pipes/ Tubes

- SS Rectangular Pipes/ Tubes

- SS Square Pipes/ Tubes

- Full comparison of the DIN and EN standards for pipes/tubes

- Stainless Steel Pipe grades comparison

Surplus stock of Steel Pipes & Tubes:

Specialist in:

Offering best price on:

Widest inventory of:

SS,CS,Alloy Steel Pipe Prices

- » Steel Pipe/ Tube Price Iran

- » Steel Pipe/ Tube Price USA

- » Steel Pipe/ Tube Price India

- » Steel Pipe/ Tube Price China

- » Steel Pipe/ Tube Price Indonesia

- » Steel Pipe/ Tube Price UK

- » Steel Pipe/ Tube Price UAE

- » Steel Pipe/ Tube Price Malaysia

- » Steel Pipe/ Tube Price Singapore

- » Steel Pipe/ Tube Price South Korea

- » Steel Pipe/ Tube Price Saudi Arabia

- » Steel Pipe/ Tube Price Japan

- » Steel Pipe/ Tube Price Thailand

- » Steel Pipe/ Tube Price Bangladesh

- » Steel Pipe/ Tube Price Canada

- » Steel Pipe/ Tube Price Germany

- » Steel Pipe/ Tube Price Australia

- » Steel Pipe/ Tube Price Nigeria

- » Steel Pipe/ Tube Price Iraq

- » Steel Pipe/ Tube Price Turkey

- » Steel Pipe/ Tube Price Brazil

- » Steel Pipe/ Tube Price Vietnam

- » Steel Pipe/ Tube Price South Africa

- » Steel Pipe/ Tube Price Egypt

- » Steel Pipe/ Tube Price Bahrain

- » Steel Pipe/ Tube Price France

- » Steel Pipe/ Tube Price Mexico

- » Steel Pipe/ Tube Price Netherlands

- » Steel Pipe/ Tube Price Taiwan

- » Steel Pipe/ Tube Price Spain

- » Steel Pipe/ Tube Price Philippines

- » Steel Pipe/ Tube Price Pakistan

- » Steel Pipe/ Tube Price Kuwait

- » Steel Pipe/ Tube Price Norway

- » Steel Pipe/ Tube Price Oman

- » Steel Pipe/ Tube Price Qatar

- » Steel Pipe/ Tube Price Russia

- » Steel Pipe/ Tube Price Slovakia

- » Steel Pipe/ Tube Price Poland

A106 Pipe

- ASTM A106 Grade A Pipe

- ASTM A106 Grade A Seamless Pipe

- A106/ SA106 Grade A Specification

- ASTM A106 Grade B Pipe

- ASTM A106 Grade B Seamless Pipe

- A106/ SA106 Grade B Specification

- ASTM A106 Grade C Pipe

- ASTM A106 Grade C Seamless Pipe

- A106/ SA106 Grade C Specification

- ASTM A106 High Temperature Seamless Carbon Steel Pipe

- A106 pipe sizes

- Comparing ASTM SA106 Gr. B and ASTM SA 53 Gr. B

- Comparing ASTM SA106 Gr. B and ASTM SA333

- ASTM A106 Seamless Pressure Pipe (See our Video)

- Pressure Ratings of Steel Pipe ASTM A53 Grade B & A106 Grade B Seamless

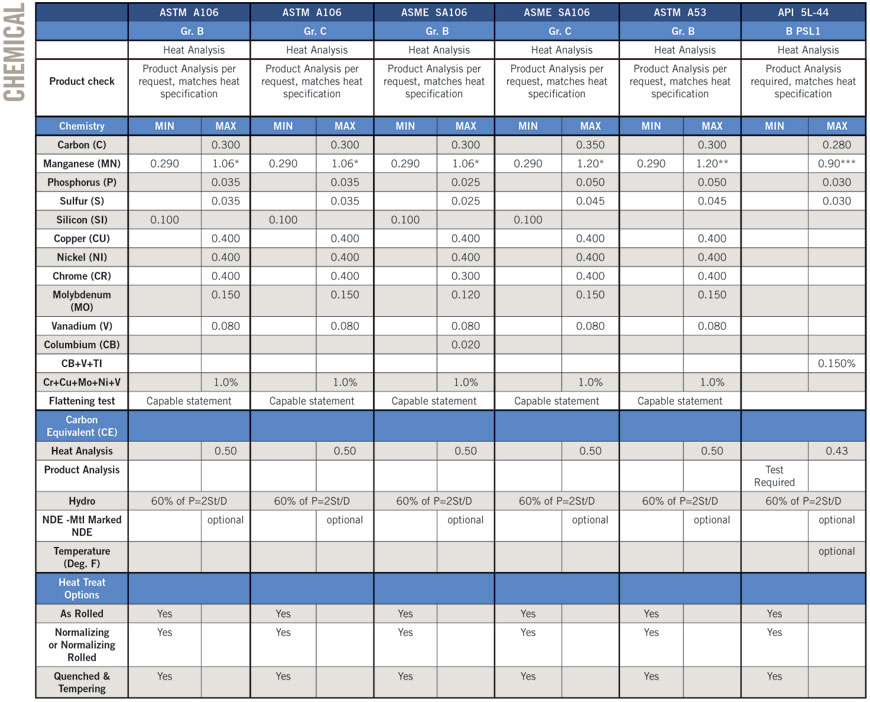

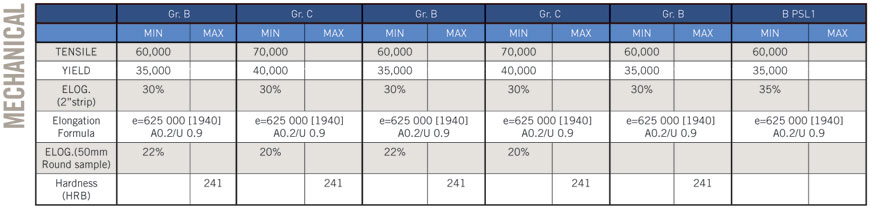

CARBON GRADE COMPARISON CHART:

ASTM A106 VS ASTM A53

For each reduction of 0.01% below the specified carbon maximum, an increase of 0.06% manganese above the specified maximum will be permitted up to a maximum of 1.50% grades X42 – X52, 1.65% above X52 – X70.

For each reduction of 0.01% below the specified carbon maximum, an increase of 0.06% manganese above the specified maximum will be permitted up to a maximum of 1.35%.

ASTM A106

Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service

1. Scope

1.1 This specification covers seamless carbon steel pipe for high-temperature service (Note 1) in NPS 1/8 to NPS 48 [DN 6 to DN 1200] (Note 2) inclusive, with nominal (average) wall thickness as given in ASME B36.10. It shall be permissible to furnish pipe having other dimensions provided such pipe complies with all other requirements of this specification. Pipe ordered under this specification shall be suitable for bending, flanging, and similar forming operations, and for welding. When the steel is to be welded, it is presupposed that a welding procedure suitable to the grade of steel and intended use or service will be utilized.

Note 1: It is suggested, consideration be given to possible graphitization.

Note 2: The dimensionless designator NPS (nominal pipe size) [DN (diameter nominal)] has been substituted in this standard for such traditional terms as "nominal diameter", "size", and "nominal size".

1.2 Supplementary requirements of an optional nature are provided for seamless pipe intended for use in applications where a superior grade of pipe is required. These supplementary requirements call for additional tests to be made and when desired shall be so stated in the order.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents. Therefore, each system is to be used independently of the other.

1.4 The following precautionary caveat pertains only to the test method portion, Sections 11, 12, and 13 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Chemical Requirements ASTM A106

| ASTM A106 Grade A | ASTM A106 Grade B | ASTM A106 Grade C | |

| Carbon,max | 0.25 (1) | 0.30 (2) | 0.35 (2) |

| Manganese | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Phosphorus,max | 0.035 | 0.035 | 0.035 |

| Sulfur,max | 0.035 | 0.035 | 0.035 |

| Silicon,min | 0.10 | 0.10 | 0.10 |

| Chrome,max (3) | 0.40 | 0.40 | 0.40 |

| Copper,max (3) | 0.40 | 0.40 | 0.40 |

| Molybdenum,max (3) | 0.15 | 0.15 | 0.15 |

| Nickel,max (3) | 0.40 | 0.40 | 0.40 |

| Vanadium,max (3) | 0.08 | 0.08 | 0.08 |

(1) For each reduction of 0.01% below the specified carbon maximum, an increase of 0.06% manganese above

the specified maximum will be permitted up to a maximum of 1.35%.

(2)Unless otherwise specified by the purchaser, for each reduction of 0.01% below the specified carbon maximum,

an increase of 0.06% manganese above the specified maximum will be permitted up to a maximum of 1.65%.

(3) These five elements combined shall not exceed 1%.

ASTM A53

Standard Spec. for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

1. Scope

1.1 This specification covers seamless and welded black and hot-dipped galvanized steel pipe in NPS 1/8 to NPS 26 [DN 6 to DN 650] (Note 1), inclusive, with nominal wall thickness (Note 2) as given in Table X2.2 and Table X2.3. It shall be permissible to furnish pipe having other dimensions provided that such pipe complies with all other requirements of this specification. Supplementary requirements of an optional nature are provided and shall apply only when specified by the purchaser.

Note 1. The dimensionless designators NPS (nominal pipe size) [DN (diameter nominal)] have been substituted in this specification for such traditional terms as "nominal diameter," "size," and "nominal size."

Note 2. The term nominal wall thickness has been assigned for the purpose of convenient designation, existing in name only, and is used to distinguish it from the actual wall thickness, which may vary over or under the nominal wall thickness.

Chemical Requirements ASTM A53

| C | Mn | P | S | Cu (1) | Ni (1) | Cr (1) | Mo (1) | V (1) | |

| Type S (seamless pipe) | |||||||||

| ASTM A53 Grade A | 0.25 | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| ASTM A53 Grade B | 0.30 | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Type E (electric-resistance-welded) | |||||||||

| ASTM A53 Grade A | 0.25 | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| ASTM A53 Grade B | 0.30 | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Type F (furnace-welded pipe) | |||||||||

| ASTM A53 Grade A | 0.30 | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

(1) The total composition for these five elements shall not exceed 1.00%.

| Specification | A106 NPS 1/8 -- 48 ANSI Schedules to 160 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Scope | Covers SEAMLESS carbon steel nominal wall pipe for high-temperature service, suitable for bending, flanging and similar forming operations. NPS 1 1/2 and under may be either hot finished or cold drawn. NPS 2 and larger shall be hot finished unless otherwise specified. |

||||||||||||||||||

| Kinds of Steel Permitted For For Pipe Material |

Killed Steel Open-hearth Electric-furnace Basic-oxygen |

||||||||||||||||||

| Hot-Dipped Galvanizing |

Not covered in specification. | ||||||||||||||||||

| Permissible Variations in Wall Thickness |

The minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified. | ||||||||||||||||||

| Tensile Requirements |

|

||||||||||||||||||

| Hydrostatic Testing |

Inspection test pressures produce a stress in the pipe wall equal to 60% or specified minimum yield strength (SMYS) at room temperature. Maximum Pressures are not to exceed 2500 psi for NPS 3 and under and 2800 psi for the larger sizes. Pressure is maintained for not less than 5 seconds. |

||||||||||||||||||

| Permissible Variations in Weights per Foot |

Weight of any length shall not vary more than 10% over and 3.5% under that specified. NOTE - NPS 4 and smaller - weighed in lots. Larger sizes - by length | ||||||||||||||||||

| Permissible Variations in Outside Diameter |

Outside Diameter at any point shall not vary from standard specified more than -

|

||||||||||||||||||

| Mechanical Tests Specified |

Tensile Test - NPS 8 and larger - either transverse or longitudinal acceptable Smaller than NPS 8 -- weighed in lots. Larger sizes -- by length. Flattening Test - NPS 2 and larger. Bending Test(Cold) - NPS 2 and under. For normal A106 uses: Degree of Bend = 90 Diameter of Mandrel = 12 x nom. dia. of pipe For close coiling: Degree of Bend = 180 Diameter of Mandrel = 8 x nom. diameter of pipe |

||||||||||||||||||

| Number of Tests Required |

|

||||||||||||||||||

| Lengths | Lengths required shall be specified on order. No "jointers" permitted unless otherwise specified. If no definite lengths required, following practice applies: Single Random -- 16' - 22'. 5% may be 12' - 16' Double Random -- Minimum length 22', Minimum average 35'. 5% may be 16' - 22'. |

||||||||||||||||||

| Required Markings on Each Length (On Tags attached to each Bundle in case of Bundled Pipe) |

Rolled Stamped or Stenciled (Mfrs. option) • Manufacturer's name or brand. • Length of pipe. • A106 A, A106 B, A106 C. ANSI schedule number. • Hydrostatic test pressure and/or NDE or NH if neither is specified • Weight per foot (NPS 4 and larger) • Additional "S" if tested supplementary requirements. |

||||||||||||||||||

| General Information |

* Unless otherwise specified, pipe furnished with plain ends. * Purchaser may specify NDE in lieu of hydrostatic test or neither. * Surface finish standards are outlined in specification. |

||||||||||||||||||

Material Grades

| High Temperature Seamless Pipe | ASTM A106 Gr. B/C, API 5L Gr. B, ASTM A53 Gr. B |

|---|---|

| Heat Exchanger Seamless Tube | ASTM A179 |

| Low Temperature Seamless Pipe | ASTM A333 Gr. 3/6 |

| Low Temperature Seamless Tube | ASTM A334 Gr. 6 |

| High Yield Seamless Pipe | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80 PSL-1/PSL-2 |

| High Yield Seamless Pipe | ISO 3183 Gr.L245, L290, L320, L360, L390, L415, L450, L485 |

| Atmospheric & Low Temp EFW Pipes | ASTM A671 Gr. CC60/CC65/CC70 |

| High Pressure & Moderate Temp EFW Pipes | ASTM A672 Gr. B60/B65/B70/C55/C60/C65/C70 |

| High Yield ERW/SAW Pipe | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80 PSL-1/PSL-2 |

| High Yield ERW/SAW Pipe | ISO 3183 Gr.L245, L290, L320, L360, L390, L415, L450, L485 |

ASTM A106 Grade B/ A106 Gr.B related industrial piping materials stock:

We also stock other stainless grades, please check the list of grades below: