No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Alloy Steel Tubes

-

Carbon Steel Pipes & Tubes

- ASTM A106 SA106 Pipe

- ASTM A53 SA53 Pipe

- ASTM A135 SA135 Pipe

- ASTM A139 SA139 Pipe

- ASTM A179 SA179 Tubes

- ASTM A210 SA210 Tubes

- ASTM A333 SA333 Pipe

- ASTM A334 SA334 Pipe

- ASTM A500 SA500 Pipe

- ASTM A501 SA501 Pipe

- ASTM A512 SA512 Tube

- ASTM A513 SA513 Tube

- ASTM A517 SA517 Tube

- ASTM A519 SA519 Tube

- ASTM A671 SA671 Pipe

- ASTM A672 SA672 Pipe

- ASTM A252 Steel piling pipe

- Carbon Steel Seamless Pipe

- Carbon Steel Pipe Japan

- Carbon Steel Pipes Europe

- Carbon Steel Pipe China

-

Stainless Steel Pipes & Tubes

- Stainless Steel Tube, Tubing & Pipe

- ASTM A271 ASME SA271 Pipes/ Tubes

- ASTM A312 ASME SA312 Pipes/ Tubes

- ASTM A358 ASME SA358 Pipes/ Tubes

- ASTM A376 ASME SA376 Pipes/ Tubes

- ASTM A409 ASME SA409 Pipes/ Tubes

- ASTM A430 ASME SA430 Pipes/ Tubes

- ASTM A632 ASME SA632 Pipes/ Tubes

- ASTM A778 ASME SA778 Pipes/ Tubes

- ASTM A813 ASME SA813 Pipes/ Tubes

- ASTM A814 ASME SA814 Pipes/ Tubes

- ASTM A826 ASME SA826 Pipes/ Tubes

- ASTM A851 ASME SA851 Pipes/ Tubes

- ASTM A213 ASME SA213 Pipes/ Tubes

- ASTM A249 ASME SA249 Pipes/ Tubes

- ASTM A268 ASME SA268 Pipes/ Tubes

- ASTM A269 ASME SA269 Pipes/ Tubes

- ASTM A270 ASME SA270 Pipes/ Tubes

- ASTM A511 ASME SA511 Pipes/ Tubes

- ASTM A688 ASME SA688 Pipes/ Tubes

-

Alloy Steel Pipes & Tubes

-

Alloy Steel Tubes

- ASTM A213 T1 Alloy Steel Tube

- ASTM A213 T2 Alloy Steel Tube

- ASTM A213 T5 Alloy Steel Tube

- ASTM A213 T5b Alloy Steel Tube

- ASTM A213 T5c Alloy Steel Tube

- ASTM A213 T9 Alloy Steel Tube

- ASTM A213 T11 Alloy Steel Tube manufacturer and suppliers

- ASTM A213 T12 Alloy Steel Tube

- ASTM A213 T17 Alloy Steel Tube

- ASTM A213 T21 Alloy Steel Tube

- ASTM A213 T22 Alloy Steel Tube

- ASTM A213 T23 Alloy Steel Tube

- ASTM A213 T24 Alloy Steel Tube

- ASTM A213 T36 Alloy Steel Tube

- ASTM A213 T91 Alloy Steel Tube

- ASTM A213 T92 Alloy Steel Tube

- ASTM A213 T122 Alloy Steel Tube

- ASTM A213 T911 Alloy Steel Tube

- ASTM A513 Grade 8620 Alloy Steel Tube

- ASTM A513 Grade 4130 Alloy Steel Tube

- ASTM A513 Grade 4118 Alloy Steel Tube

- ASTM A513 Grade 4140 Alloy Steel Tube

- ASTM A513 Grade 8630 Alloy Steel Tube

-

Alloy Steel Pipes

- ASTM A335 P1 Alloy Steel Pipe

- ASTM A335 P2 Alloy Steel Pipe

- ASTM A335 P5 Alloy Steel Pipe

- ASTM A335 P5b Alloy Steel Pipe

- ASTM A335 P5c Alloy Steel Pipe

- ASTM A335 P9 Alloy Steel Pipe

- ASTM A335 P11 Alloy Steel Pipe Manufacturer & Suppliers

- ASTM A335 P12 Alloy Steel Pipe

- ASTM A335 P15 Alloy Steel Pipe

- ASTM A335 P21 Alloy Steel Pipe

- ASTM A335 P22 Alloy Steel Pipe Manufacturer and suppliers

- ASTM A335 P23 Alloy Steel Pipe

- ASTM A335 P24 Alloy Steel Pipe

- ASTM A335 P36 Alloy Steel Pipe

- ASTM A335 P91 Alloy Steel Pipe

- ASTM A335 P92 Alloy Steel Pipe

- ASTM A335 P122 Alloy Steel Pipe

- ASTM A335 P911 Alloy Steel Pipe

- Alloy Steel Pipe & Tube Specification

-

Alloy Steel Tubes

- Special Steel Grades Pipes & Tubes

- API 5L Pipe

- Titanium Pipes & Tubes

- Welded/ ERW Pipes

- Mild Steel Pipes & Tubes

- Ductile Iron Spun Pipe & Ductile Iron Flanged Pipe Cast

- Capillary Tube| Capillary Tubing

- Boiler Tube

- Heat exchanger tubes

- Cupro Nickel Tube

- Aluminium Tube

- Corten Steel Pipes & Tubes

- EIL Approved Pipes

- IBR Pipe/ Tube & Non IBR Pipe/ Tube

- Black Pipes

- Galvanised Steel Pipes/ GI Tubes

- SS Coiled Tubing/ Tubes

- SS Electropolished Pipes/ Tubes

- SS Rectangular Pipes/ Tubes

- SS Square Pipes/ Tubes

- Full comparison of the DIN and EN standards for pipes/tubes

- Stainless Steel Pipe grades comparison

Surplus stock of Steel Pipes & Tubes:

Specialist in:

Offering best price on:

Widest inventory of:

SS,CS,Alloy Steel Pipe Prices

- » Steel Pipe/ Tube Price Iran

- » Steel Pipe/ Tube Price USA

- » Steel Pipe/ Tube Price India

- » Steel Pipe/ Tube Price China

- » Steel Pipe/ Tube Price Indonesia

- » Steel Pipe/ Tube Price UK

- » Steel Pipe/ Tube Price UAE

- » Steel Pipe/ Tube Price Malaysia

- » Steel Pipe/ Tube Price Singapore

- » Steel Pipe/ Tube Price South Korea

- » Steel Pipe/ Tube Price Saudi Arabia

- » Steel Pipe/ Tube Price Japan

- » Steel Pipe/ Tube Price Thailand

- » Steel Pipe/ Tube Price Bangladesh

- » Steel Pipe/ Tube Price Canada

- » Steel Pipe/ Tube Price Germany

- » Steel Pipe/ Tube Price Australia

- » Steel Pipe/ Tube Price Nigeria

- » Steel Pipe/ Tube Price Iraq

- » Steel Pipe/ Tube Price Turkey

- » Steel Pipe/ Tube Price Brazil

- » Steel Pipe/ Tube Price Vietnam

- » Steel Pipe/ Tube Price South Africa

- » Steel Pipe/ Tube Price Egypt

- » Steel Pipe/ Tube Price Bahrain

- » Steel Pipe/ Tube Price France

- » Steel Pipe/ Tube Price Mexico

- » Steel Pipe/ Tube Price Netherlands

- » Steel Pipe/ Tube Price Taiwan

- » Steel Pipe/ Tube Price Spain

- » Steel Pipe/ Tube Price Philippines

- » Steel Pipe/ Tube Price Pakistan

- » Steel Pipe/ Tube Price Kuwait

- » Steel Pipe/ Tube Price Norway

- » Steel Pipe/ Tube Price Oman

- » Steel Pipe/ Tube Price Qatar

- » Steel Pipe/ Tube Price Russia

- » Steel Pipe/ Tube Price Slovakia

- » Steel Pipe/ Tube Price Poland

View larger

View larger

ASTM A213/ ASME SA213 T24

Other Trade name: ASTM A213 & ASME SA213, ASTM A213 T9 /T11 /T12 /T5 /T91 / T2/ T5/ T5b/ T5c/ T22/ T23 /T92, Chrome Moly Alloy Heater Tubes, Chrome Moly Alloy A213 / SA213 Heater Tubes

Calculate Your Pipe Weight

(It will open in new window)

New

More info

ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes Manufacturer

ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes ASTM A213 T9 /T11 /T12 /T5 /T91 / T2/ T5/ T5b/ T5c/ T22/ T23 /T92

Are you looking for a vendor for all your ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes needs? MD Exports LLP Pipes is a premier worldwide manufacturer & supplier of ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes, ASTM SA213 T9 /T11 /T12 /T5 /T91 / T2/ T5/ T5b/ T5c/ T22/ T23 /T92

MD Exports LLP Pipes is a export unit of MD Exports LLPs Pvt. Ltd. We are manufacturers, stockists & suppliers of ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes, ASTM SA213 T9 /T11 /T12 /T5 /T91 / T2/ T5/ T5b/ T5c/ T22/ T23 /T92. This specification covers nominal wall and minimum wall seamless ferritic alloy-steel pipe intended for high-temperature service. ASTM A335 pipe ordered to this specification shall be suitable for fusion welding, bending, flanging (vanstoning), and similar forming operations. Each grade of ASTM A213 having unique properties, execution, tolerances, lengths, and mechanical & chemical properties. Different grades used in different atmosphere depends upon temperature, pressure & climatically conditions.

But as of now there is no website providing comparisons of all grades of Alloy Steel pipes in a single window.MD Exports LLP Pipes is come up first time an online platform where project consultants & engineers get detailed specification, differences & comparison between 3-4 grades of Chrome Moly Alloy Seamless Pipe in a single window. It will help a lot you to choose right Chrome Moly Alloy Seamless Tube with appropriate grade with best price. It will also help to prevent breakage & damage of Oil & gas Pipe line. Our experts, those have worked with leading manufacturers of SA335 Tube can also provide you free consultancy about Life of each grade of Chrome Moly Tube including ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes, ASTM SA213 T9 /T11 /T12 /T5 /T91 / T2/ T5/ T5b/ T5c/ T22/ T23 /T92 in different conditions. It will help a lot to choose right SA213 Tubing with appropriate grade with best price.

You can also search any size & grade in steel seamless pipe to compare pricing. Before you buy ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes you must check our free sample, we are offering best price in Asia.

ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

Types of SA213 Tubing

MD Exports LLP Steel presence:

MD Exports LLP has sales Representative & Stockyard in Netherlands, Venezuela, South Africa, Indonesia, USA, UAE & Australia, in our UAE stockyard we have ready stock of ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes,ASTM SA213 Grade T9 /T11 /T12 /T5 /T91 / T2/ T5/ T5b/ T5c/ T22/ T23 /T92, Seamless Steel Pipe, P22 Pipe, sa213 t11, S/A 53, API 5L Line Pipe & A 106 Grade B Pipe of world's renowned manufacturers like Tenaris / Dalmine-Italy,Vallourec-Europe, Vallourec Star-USA, Productos Tubulares-Spain, Jiangu Chengde Steel Tube-China, Tubos Reunidos-Spain, Chomutov-Czech Republic, Huta Batory-Poland, Siderca-Argentina, Mittal Steel-Czech Republic Romania, NKK/ MSL -India / Tenaris Japan, Volzhsky Russia, Tamsa-Mexico, Productos Tubulares-Spain, Niko Tube-Ukraine, Heng Yeng-China, Lubao Steel China Suzhou Seamless-China and YYC-China etc.

You can visit our UAE Stockyard to check piping material before you buy,

![]() Our UAE stockyard address is:

Our UAE stockyard address is:

F14 Street, Al Hamra Free Zone,

Al Jazeera, Ras Al Khaimah, UAE,

Whenever you want to visit our UAE or other location stockyard please contact us to set-up an appointment. From our UAE stockyard, we are catering urgent delivery requirements from Oman, Qatar, Egypt, Turkey, Kuwait, Bahrain, Saudi Arabia, Sudan, Turkmenistan, Afghanistan, Iran & Iraq.

ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes Specification

|

Standard Specifications for Seamless Ferritic and Austenitic Alloy-Steel for boilers, superheaters, and heat-exchangers |

|

|

Applications: |

For manufacturing wall panel,economizers, superheaters and steam pipelines for boilers |

|

Size (mm): |

O.D.: 28-168; W.T.: 2∼30; L: max 12000 |

ASME SA-213 T24 in the American standard U bend alloy steel pipe/tube

Grade: SA213 T24

Standard: ASME SA-213/SA-213M

Product type: Hot rolled welded steel tube, seamless pipe, U bend alloy steel pipe, stainless steel material

Process: Cold finished or hot finished

Size: according to order

Stock: Available

MTC: Available

ASTM A213 Grade T24 Properties

| ASTM A213 Grade T24 Chemical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Carbon | Silicon | Manganese | Phosphorous | Sulphur | Molybdenum | Nickel | Chromium | Copper | Others |

| 0.05-0.10 | 0.15-0.45 | 0.30-0.70 | 0.02 | 0.01 | 0.90-1.10 | – | 2.20-2.60 | – | – |

| ASTM A213 Grade T24 Mechanical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Yield Strength | Tensile Strength | Elongation A5 min | |||||||

| MPa min | ksi min | MPa min | MPa min | ksi min | Percentage | ||||

| 415 | – | 60 | 30 | ||||||

| ASTM A213 Grade T24 Equivalent Designation | |||||

|---|---|---|---|---|---|

| DIN | EN | BS | NFA | ASTM | ASME |

| – | EN 7CrMoVTiB10-10 | – | ASTM A213 Grade T24 | ASME SA 213 Grade T24 | – |

-

World standard comparative table

KS

ASTM

JIS

DIN

BS

Grade number

GRADE

Grade number

GRADE

Grade number

GRADE

Grade number

GRADE

Grade number

GRADE

D 3572

STHA12

A161

A209T1

T1G 3462

STBA12

17175

15Mo 3

-

-

STHA13

A209

T1a

STBA13

-

-

-

-

STHA20

A213

T2

STBA20

-

-

-

-

STHA22

STBA22

17175

13Cr Mo 44

3059

S1 620

S2 620

ERW620

CEW620STHA23

A199

A200

A213T11

T11

T11STBA23

-

-

-

-

STHA24

A199

A200

A213T22

T22

T22STBA24

17175

10Cr Mo910

3059

S1 622-440

S2 622-440STHA25

A199

A200

A210T5

T5

T5STBA25

-

-

-

-

STHA26

A199

A200

A213T9

T9

T9STBA26

-

-

-

-

-

A335 Useful Info

ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes Heat Treatment Requirements

P5, P9, P11, and P22 Grade Heat Treatment Type Normalizing Temperature Range F [C] Subcritical Annealing

or Tempering

Temperature Range F

[C]T5 (b,c) Full or Isothermal Anneal Normalize and Temper ***** 1250 [675] Subcritical Anneal (P5c only) ***** 1325 - 1375 [715 - 745] T9 Full or Isothermal Anneal Normalize and Temper ***** 1250 [675] T11 Full or Isothermal Anneal Normalize and Temper ***** 1200 [650] T22 Full or Isothermal Anneal Normalize and Temper ***** 1250 [675] T91 Normalize and Temper 1900-1975 [1040 - 1080] 1350-1470 [730 - 800] Quench and Temper 1900-1975 [1040 - 1080] 1350-1470 [730 - 800] Chemical Requirements for ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes

Grade T-5 T-9 T-11 T-22 T-91 T-91 shall also include the following: Element UNS Designation K41545 S50400 K11597 K21590 K91560 Carbon 0.15 max 0.15 max 0.05 - 0.15 0.05 - 0.15 0.08 - 0.12 V at 0.18 - 0.25 Manganese 0.30 - 0.60 0.30 - 0.60 0.30 - 0.60 0.30 - 0.60 0.30 - 0.60 N at 0.030 - 0.070 Phosphorous, max 0.025 0.025 0.025 0.025 0.020 Ni at 0.40 max Sulfur, max 0.025 0.025 0.025 0.025 0.010 Al at 0.02 max Silicon 0.50 max 0.25 - 1.00 0.50 - 1.00 0.50 max 0.20 -0.50 Cb at 0.06 - 0.10 Chromium 4.00 - 6.00 8.00 - 10.00 1.00 - 1.50 1.90 - 2.60 8.00 - 9.50 Ti at 0.01 max Molybdenum 0.45 -0.65 0.90 - 1.10 0.44 - 0.65 0.87 - 1.13 0.85 - 1.05 Zr at 0.01 max Tensile Requirements for ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes

Seamless P-5 P-9 P-11 P-22 *P-91 Tensile Strength, min., psi ksi 60 60 60 60 85 MPa 415 415 415 415 585 Yield Strength, min., psi ksi 30 30 30 30 60 MPa 205 205 205 205 415 * P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC].

ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes Permissible Variation in Wall Thickness

NPS [DN] Designator Tolerance, % from Specified Over Under 1/8 to 2 1/2 [6 to 65] incl., all t/D ratios 20.0% 12.5% Above 2 1/2 [65], t/D < or = 5% 22.5% 12.5% Above 2 1/2 [65], t/D > 5% 15.0% 12.5% (t = Specified Wall Thickness; D = Specified Outside Diameter)

Elongation Requirements for ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes

Calculated Minimum Elongation Values Elongation in 2 in. or 50 mm, min % Wall ThicknessT5, T9, T11, P22 P91 in. mm Longitudinal Transverse Longitudinal 5/16 (0.312) 8 30 20 20 9/32 (0.281) 7.2 28 19 19 1/4 (0.250) 6.4 27 18 18 7/32 (0.219) 5.6 26 17 3/16 (0.188) 4.8 24 16 5/32 (0.156) 4 22 15 7/8 (0.125) 3.2 21 14 3/32 (0.094) 2.4 20 13 1/18 (0.062) 1.6 18 12 ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes Permissible Variations in Outside Diameter

Outside Diameter at any point shall not vary from standard specified more than:

NPS [DN] Designator Over Under in. mm in. mm 1/8 to 1 1/2 [6 to 40], incl. 1/64 (0.015) 0.40 1/64 (0.015) 0.40 Over 1 1/2 to 4 [40 to 100], incl. 1/32 (0.031) 0.79 1/32 (0.031) 0.79 Over 4 to 8 [100 to 200], incl. 1/16 (0.062) 1.59 1/32 (0.031) 0.79 Over 8 to 12 [200 to 300], incl. 3/32 (0.093) 2.38 1/32 (0.031) 0.79 Over 12 [300] +/- 1% of the specified outside diameter ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes Mechanical Tests Specified

Transverse or Longitudinal Tension Test and Flattening Test, Hardness Test, or Bend Test For material heat treated in a batch-type furnace, tests shall be made on 5% of the pipe from each treated lot. For small lots, at least one pipe shall be tested. For material heat treated by the continuous process, tests shall be made on a sufficient number of pipe to constitute 5% of the lot, but in no case less than 2 pipe. Notes for Hardness Test: P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC]. Notes for Bend Test: For pipe whose diameter exceeds NPS 25 and whose diameter to wall thickness ratio is 7.0 or less shall be subjected to the bend test instead of the flattening test. Other pipe whose diameter equals or exceeds NPS 10 may be given the bend test in place of the flattening test subject to the approval of the purchaser. The bend test specimens shall be bent at room temperature through 180 without cracking on the outside of the bent portion. The inside diameter of the bend shall be 1 inch [25 mm]. Hydrostatic Test Each length of Tube shall be Hydro tested, at option of manufacture nondestructive electric testing can be used.

-

Material Comparison Tables

Material Comparison Tables (ASTM →KS, JIS, DIN, BS, NBN, NF, UNI)

A 199: Seamless Cold Drawn Intermediate Alloy Steel Heat Exchange and Condenser Tubes

ASTM STANDARDUNS NO.KOREA/JAPANESGERMAN

BRITISHBELGIANFRENCHITALIANKS/JIS SymbolKS/JIS NumbeDIN TypeDIN

Number

Materiral

Number

B.S

Number

B.S GradeNBN TypeNBN GradeAFNOR TypeUNI TypeUNI NumberT5K41545 STHA 24 / STBA 25 D3572 / G3462 12 CrMo 19 5 1.7362 3606 CFS 625 X 12 Cr Mo 5 837 Z 12 CD 5.05 T11K11597 STHA 22 / STBA 23 D3572 / G3462 13 CrMo 44 17175 1.7335 3606 CFS 621 10 CD 5.05 T22K21590 STHA 23 / STBA 24 D3572 / G3462 10 CrMo 9 10 17175 1.7380 3606 CFS 622 10 Cr Mo 9 10 837 10 CD 9.10 12CrMo 9 10 5462 Material Comparison Tables (ASTM →KS, JIS, DIN, BS, NBN, NF, UNI)

A 200: Seamless Intermediate Alloy Steel Still Tubes for Refinery Service

ASTMSTANDARDUNS NO.KOREA/JAPANESGERMAN

BRITISHBELGIANFRENCHITALIANKS/JIS SymbolKS/JIS NumbeDIN TypeDIN

Number

Materiral

Number

B.S

Number

B.S GradeNBN TypeNBN GradeAFNOR TypeNF NumberUNI TypeUNI NumberT 5K41545 STHA 24 / STBA 25 D3572 / G3462 12 CrMo 19 5 1.7362 3604 625 X12CrMo 837 TU Z 12 CD A49-213 T 11K11597 STHA 22 / STBA 23 D3572 / G3462 13 CrMo 44 17175 1.7335 3604 621 5.05 A49-213 T 22K2159 STHA 23 / STBA 24 F3572 / G3462 10 CrMo 9 10 17175 1.7380 3606 622 10 CrMo 9 10 837 TU 10 CD 5.05 A49-213 12CrMo 9 10 5462 TU 12 CD 9.10 Material Comparison Tables (ASTM →KS, JIS, DIN, BS, NBN, NF, UNI)

A 209 : Seamless C-Mo Steel Boiler and Superheater Tubes

ASTM STANDARDUNS NO.KOREA/JAPANESGERMAN

FRENCHITALIANKS/JIS SymbolKS/JIS NumbeRemarksDIN TypeDIN

Number

Materiral

Number

RemarksAFNOR TypeNF NumberUNI TypeUNI NumberGrade T 1 K11522 STHA 12 / STBA 12 D3572 / G3462 (30)(24) 16 Mo 5 1.5423 (3a) 18 MD 4.05 16 Mo5 5462 Grade T 1a K12023 STHA 13 /STBA 13 D3572 / G3462 (30)(24) 16 Mo 5 1.5423 (3a) Material Comparison Tables (ASTM →KS, JIS, DIN, BS, NBN, NF, UNI)

A 213: Seamless Alloy Steel Boiler and Heat Exchanger Tubes

ASTM STANDARDUNS NO.KOREA/JAPANESGERMAN

BRITISHFRENCHITALIANKS/JIS SymbolKS/JIS NumbeDIN TypeDIN

NumberMateriral

NumberB.S

NumberB.S GradeAFNOR TypeNF NumberUNI TypeUNI NumberGrade T 5 K41545 STHA 24 / STBA 25 D3572 / G3462 12 CrMo 19 5 1.7362 3606 625 TUZ12C A49-213 Grade T 11 K11597 STHA 22 / STBA 24 D3572 / G3462 13 CrMo 44 17175 1.7335 3606 621 5.05 Grade T 12 K11562 STHA 21 / STBA 22 D3572 / G3462 13 CrMo 44

17175 1.7335 3606 620 TU 10 CD 5.05 Grade T 22 K21590 STHA 23 / STBA 24 D3572 / G3462 10 CrMo 9 10 17175 1.7380 3606 622 12 CrMo 9 10 5462 TP 304 S30400 STS 304 TB / SUS 304 TB D3577 / G3463 X5 CrNi 18 9 17440 1.4301 3606 304S25 TU 10 CD 9.10 A49-218 X5 CrNi 18 10 6904 TP 304L S31403 STS 304LTB / SUS 304LTB D3577 / G3463 X2 CrNi 18 9 17440 1.4306 3606 304S22 Z 6 CN 18.09 A49-218 X2 CrNi 18 11 6904

ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes Marking & Packaging

- Each ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes is marked with tube type, heat number, steel grade and size. Other markings, such as stamping, can be made on request.

- Painted Stenciled or Die Stamped

- Manufacturer's name or mark, size, weight per foot, grade, process of manufacture, type of steel, length (NPS 4 and larger only). Test pressure when hogher than tabulated (NPS 2 and larger only). Heat treat symbols, as applicable - HN, HS, HA or HQ.

|

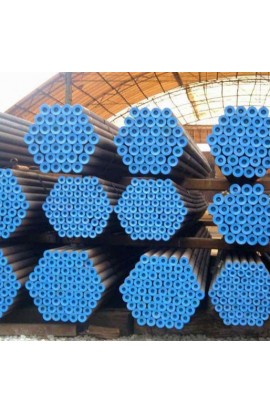

ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes packed in MD Exports LLP's stockyard |

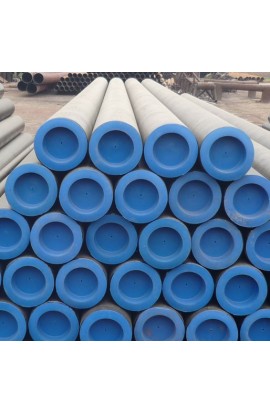

ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes packed for shipping |

SEA WORTHY PACKING: Hexagonal shaper bundled with strong steel strips. Plastic caps on both of the pipes. Other types of packing can be made according to the customer's requirements

As we are supplying ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes globally so we have our dedicated sales representatives & technical consultant engineer in Nigeria, South Africa, Australia, Italy, Iran, Iraq, Israel, Turkey, Spain, Indonesia, Saudi Arabia, Oman, Qatar, Kuwait, South Korea, Canada, Japan, Yemen, Netherlands, Singapore, Malaysia who can provide you detailed information about ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes & comparison with other grades which will help you to choose the right steel pipe for your project at lowest price available in the market. For free consultancy or technical query you can send mail to our technical experts.

ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes related Chorme-Moly Tube materials stock list:

We also stock Chorme-Moly other grades, please check the list of Alloy Steel grades below:

Send Steel Tubing Quick Enquiry:

India's Largest Stockist & Dealers of ASME S/A213 Chorme-Moly Tubing

Looking for ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes? First time in India selling steel Pipe & ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes online at lowest price with all shipping documents, supplying ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes with mill certificate, all size & grades seamless pipes is in ready stock, Hot offer - flat 5% off on ASTM A213/ ASME SA213 T24 Chrome Moly Seamless Tubes

Reviews

No customer comments for the moment.

Summary

- Product Name:ASTM A213/ ASME SA213 T24

- Price: $ 3.00

- Product Width: 0.00 cm

- Product Height: 0.00 cm

- Product Depth: 0.00 cm

- Product Weight: 0.00 kg

- Description: Other Trade name: ASTM A213 & ASME SA213, ASTM A213 T9 /T11 /T12 /T5 /T91 / T2/ T5/ T5b/ T5c/ T22/ T23 /T92, Chrome Moly Alloy Heater Tubes, Chrome Moly Alloy A213 / SA213 Heater Tubes Calculate Your Pipe Weight (It will open in new window)