Product successfully added to your shopping cart

There are 20 items in your cart. There is 1 item in your cart.

API 5L Seamless Pipes

-

Carbon Steel Pipes & Tubes

- ASTM A106 SA106 Pipe

- ASTM A53 SA53 Pipe

- ASTM A135 SA135 Pipe

- ASTM A139 SA139 Pipe

- ASTM A179 SA179 Tubes

- ASTM A210 SA210 Tubes

- ASTM A333 SA333 Pipe

- ASTM A334 SA334 Pipe

- ASTM A500 SA500 Pipe

- ASTM A501 SA501 Pipe

- ASTM A512 SA512 Tube

- ASTM A513 SA513 Tube

- ASTM A517 SA517 Tube

- ASTM A519 SA519 Tube

- ASTM A671 SA671 Pipe

- ASTM A672 SA672 Pipe

- ASTM A252 Steel piling pipe

- Carbon Steel Seamless Pipe

- Carbon Steel Pipe Japan

- Carbon Steel Pipes Europe

- Carbon Steel Pipe China

-

Stainless Steel Pipes & Tubes

- Stainless Steel Tube, Tubing & Pipe

- ASTM A271 ASME SA271 Pipes/ Tubes

- ASTM A312 ASME SA312 Pipes/ Tubes

- ASTM A358 ASME SA358 Pipes/ Tubes

- ASTM A376 ASME SA376 Pipes/ Tubes

- ASTM A409 ASME SA409 Pipes/ Tubes

- ASTM A430 ASME SA430 Pipes/ Tubes

- ASTM A632 ASME SA632 Pipes/ Tubes

- ASTM A778 ASME SA778 Pipes/ Tubes

- ASTM A813 ASME SA813 Pipes/ Tubes

- ASTM A814 ASME SA814 Pipes/ Tubes

- ASTM A826 ASME SA826 Pipes/ Tubes

- ASTM A851 ASME SA851 Pipes/ Tubes

- ASTM A213 ASME SA213 Pipes/ Tubes

- ASTM A249 ASME SA249 Pipes/ Tubes

- ASTM A268 ASME SA268 Pipes/ Tubes

- ASTM A269 ASME SA269 Pipes/ Tubes

- ASTM A270 ASME SA270 Pipes/ Tubes

- ASTM A511 ASME SA511 Pipes/ Tubes

- ASTM A688 ASME SA688 Pipes/ Tubes

-

Alloy Steel Pipes & Tubes

-

Alloy Steel Tubes

- ASTM A213 T1 Alloy Steel Tube

- ASTM A213 T2 Alloy Steel Tube

- ASTM A213 T5 Alloy Steel Tube

- ASTM A213 T5b Alloy Steel Tube

- ASTM A213 T5c Alloy Steel Tube

- ASTM A213 T9 Alloy Steel Tube

- ASTM A213 T11 Alloy Steel Tube manufacturer and suppliers

- ASTM A213 T12 Alloy Steel Tube

- ASTM A213 T17 Alloy Steel Tube

- ASTM A213 T21 Alloy Steel Tube

- ASTM A213 T22 Alloy Steel Tube

- ASTM A213 T23 Alloy Steel Tube

- ASTM A213 T24 Alloy Steel Tube

- ASTM A213 T36 Alloy Steel Tube

- ASTM A213 T91 Alloy Steel Tube

- ASTM A213 T92 Alloy Steel Tube

- ASTM A213 T122 Alloy Steel Tube

- ASTM A213 T911 Alloy Steel Tube

- ASTM A513 Grade 8620 Alloy Steel Tube

- ASTM A513 Grade 4130 Alloy Steel Tube

- ASTM A513 Grade 4118 Alloy Steel Tube

- ASTM A513 Grade 4140 Alloy Steel Tube

- ASTM A513 Grade 8630 Alloy Steel Tube

-

Alloy Steel Pipes

- ASTM A335 P1 Alloy Steel Pipe

- ASTM A335 P2 Alloy Steel Pipe

- ASTM A335 P5 Alloy Steel Pipe

- ASTM A335 P5b Alloy Steel Pipe

- ASTM A335 P5c Alloy Steel Pipe

- ASTM A335 P9 Alloy Steel Pipe

- ASTM A335 P11 Alloy Steel Pipe Manufacturer & Suppliers

- ASTM A335 P12 Alloy Steel Pipe

- ASTM A335 P15 Alloy Steel Pipe

- ASTM A335 P21 Alloy Steel Pipe

- ASTM A335 P22 Alloy Steel Pipe Manufacturer and suppliers

- ASTM A335 P23 Alloy Steel Pipe

- ASTM A335 P24 Alloy Steel Pipe

- ASTM A335 P36 Alloy Steel Pipe

- ASTM A335 P91 Alloy Steel Pipe

- ASTM A335 P92 Alloy Steel Pipe

- ASTM A335 P122 Alloy Steel Pipe

- ASTM A335 P911 Alloy Steel Pipe

- Alloy Steel Pipe & Tube Specification

-

Alloy Steel Tubes

- Special Steel Grades Pipes & Tubes

- API 5L Pipe

- Titanium Pipes & Tubes

- Welded/ ERW Pipes

- Mild Steel Pipes & Tubes

- Ductile Iron Spun Pipe & Ductile Iron Flanged Pipe Cast

- Capillary Tube| Capillary Tubing

- Boiler Tube

- Heat exchanger tubes

- Cupro Nickel Tube

- Aluminium Tube

- Corten Steel Pipes & Tubes

- EIL Approved Pipes

- IBR Pipe/ Tube & Non IBR Pipe/ Tube

- Black Pipes

- Galvanised Steel Pipes/ GI Tubes

- SS Coiled Tubing/ Tubes

- SS Electropolished Pipes/ Tubes

- SS Rectangular Pipes/ Tubes

- SS Square Pipes/ Tubes

- Full comparison of the DIN and EN standards for pipes/tubes

- Stainless Steel Pipe grades comparison

Surplus stock of Steel Pipes & Tubes:

Specialist in:

Offering best price on:

Widest inventory of:

SS,CS,Alloy Steel Pipe Prices

- » Steel Pipe/ Tube Price Iran

- » Steel Pipe/ Tube Price USA

- » Steel Pipe/ Tube Price India

- » Steel Pipe/ Tube Price China

- » Steel Pipe/ Tube Price Indonesia

- » Steel Pipe/ Tube Price UK

- » Steel Pipe/ Tube Price UAE

- » Steel Pipe/ Tube Price Malaysia

- » Steel Pipe/ Tube Price Singapore

- » Steel Pipe/ Tube Price South Korea

- » Steel Pipe/ Tube Price Saudi Arabia

- » Steel Pipe/ Tube Price Japan

- » Steel Pipe/ Tube Price Thailand

- » Steel Pipe/ Tube Price Bangladesh

- » Steel Pipe/ Tube Price Canada

- » Steel Pipe/ Tube Price Germany

- » Steel Pipe/ Tube Price Australia

- » Steel Pipe/ Tube Price Nigeria

- » Steel Pipe/ Tube Price Iraq

- » Steel Pipe/ Tube Price Turkey

- » Steel Pipe/ Tube Price Brazil

- » Steel Pipe/ Tube Price Vietnam

- » Steel Pipe/ Tube Price South Africa

- » Steel Pipe/ Tube Price Egypt

- » Steel Pipe/ Tube Price Bahrain

- » Steel Pipe/ Tube Price France

- » Steel Pipe/ Tube Price Mexico

- » Steel Pipe/ Tube Price Netherlands

- » Steel Pipe/ Tube Price Taiwan

- » Steel Pipe/ Tube Price Spain

- » Steel Pipe/ Tube Price Philippines

- » Steel Pipe/ Tube Price Pakistan

- » Steel Pipe/ Tube Price Kuwait

- » Steel Pipe/ Tube Price Norway

- » Steel Pipe/ Tube Price Oman

- » Steel Pipe/ Tube Price Qatar

- » Steel Pipe/ Tube Price Russia

- » Steel Pipe/ Tube Price Slovakia

- » Steel Pipe/ Tube Price Poland

View larger

View larger

API 5L X80 Pipe suppliers

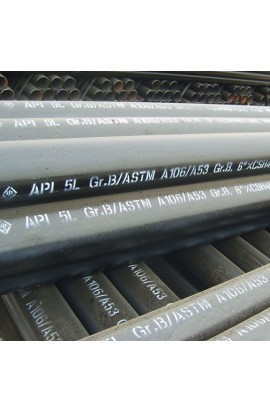

Other Trade name: API 5L Seamless Line Pipe, X52 Grade Steel Pipe, API 5L X52, 5L X56, 5L X60, 5L X65, 5L X70 X80 PSL1/ PSL2 Pipe, API 5L Line Pipe, api 5lx pipe, api 5l grade b

Calculate Your Pipe Weight

(It will open in new window)

New

More info

API 5L X80 Pipe Grade B, x42, x46 x56, x60, x70, x80 Carbon Steel Seamless Pipe

API 5L X80 Pipe api5l pipe, api5l-b, api5l X52 X60 X65, api5l psl2 & api5l grb Carbon Steel Pipe

Manufacturers, stockists & suppliers of API 5L X80 Pipe x52 pipe, x42 pipe, x70 pipe, x65 pipe, x60 pipe, x56 pipe, x80 pipe, PSL-1 PSL-2 pipes

MD Exports LLP Pipes is a export unit of MD Exports LLPs Pvt. Ltd. We are manufacturers, stockists & suppliers of API 5L X80 Pipe, This is steel pipe for pipeline transportation systems in the petroleum and natural gas industries. API 5L Grade B Seamless & Welded Line pipe is used mainly in Oil & Gas industry where they need to setup very long pipeline but in API line pipe there are so many grades like API 5L A25 (and the following "X" Grades), X42, X46, X52, X56, X60, X65, X70, X80 PSL-1, PSL-2.

Each grade of API 5L having unique properties, Yield strength, Tensile strength, & hardness. Different grades used in different atmosphere depends upon temperature, pressure & climatically conditions. But as of now there is no website providing comparisons of all grades of API line pipes in a single window. MD Exports LLP Pipes is come up first time an online platform where project consultants & engineers get differences & comparison between 3-4 grades of API 5l Gr.B Pipe in a single window. It will help a lot to choose right API Line pipe with appropriate grade with best price.

You can search any size & grade in steel seamless pipe to compare pricing. Before you buy API 5L X80 Pipe you must check our free sample, we are offering best price in Asia.

Types of API 5L Grade B Seamless PipeMD Exports LLP Pipes stocks a full range of API 5L X52 PSL-1 & PSL-2 line pipe in seamless, we are manufacturing & supplying 10 grades of API 5L line pipe seamless and welded (ERW / HFW) :

|

MD Exports LLP Steel presence:

MD Exports LLP has sales Representative & Stockyard in Netherlands, Venezuela, South Africa, Indonesia, USA, UAE & Australia, in our UAE stockyard we have ready stock of API 5L X80 Pipe,x52 pipe, x42 pipe, x70 pipe, x65 pipe, x60 pipe, x56 pipe, x80 pipe, psl2 pipe, ERW Steel Pipe, LSAW Steel Pipe, Seamless Steel Pipe, P22 Pipe, sa213 t11, S/A 53, API 5L Line Pipe & A 106 Grade B Pipe of world's renowned manufacturers like Tenaris / Dalmine-Italy,Vallourec-Europe, Vallourec Star-USA, Productos Tubulares-Spain, Jiangu Chengde Steel Tube-China, Tubos Reunidos-Spain, Chomutov-Czech Republic, Huta Batory-Poland, Siderca-Argentina, Mittal Steel-Czech Republic Romania, NKK/ MSL -India / Tenaris Japan, Volzhsky Russia, Tamsa-Mexico, Productos Tubulares-Spain, Niko Tube-Ukraine, Heng Yeng-China, Lubao Steel China Suzhou Seamless-China and YYC-China etc.

You can visit our UAE Stockyard to check piping material before you buy,

![]() Our UAE stockyard address is:

Our UAE stockyard address is:

F14 Street, Al Hamra Free Zone,

Al Jazeera, Ras Al Khaimah, UAE,

Whenever you want to visit our UAE or other location stockyard please contact us to set-up an appointment. From our UAE stockyard, we are catering urgent delivery requirements from Oman, Qatar, Egypt, Turkey, Kuwait, Bahrain, Saudi Arabia, Sudan, Turkmenistan, Afghanistan, Iran & Iraq.

API 5L X80 Pipe Specification

API 5L X80 Pipe are carbon steel pipes, strictly manufactured as per API (AMERICAN PETROLEUM INSTITUTE) to meet the clients requirements. API 5L X80 Pipe are provided with multiple end connections like non-Upset ends and External Upset Ends. MD Exports LLP Pipes provides these api pipes with all mandatory non-destructive testing inclusive of eddy current tests, hydro testing. We offer API 5L pipes with both galvanized and black finish in single random length i.e 4-7 metres and double random lengths i.e 7-13 metres. In General these api pipes are used to transit oil, gas and petroleum distilleries. Among all API x series pipe x52 is the most selling API grade.

MD Exports LLP Pipes is exclusively engaged in stocking and manufacturing API 5L X80 Pipe with certifications confirming to EN 10204- 3.1/3.2. Line pipe is available in sizes ranging from 0.500 to 100 inches and can be produced by seamless, ERW, SAWL and SAWH methods according to API Spec 5L, CSA, DIN EN, BS EN and DNV standards. To check the api5l pipe specification please check below table. Grade X65 PSL2 pipes are available in seamless and welded types, commercially known as API 5L line pipes. The technical committee authoring the standards recognized that there are two basic Product Specifications Levels (PSL) of technical requirements and therefore developed PSL 1 and PSL 2. PSL 1 is a standard quality for line pipe where PSL 2 contains additional chemical, mechanical properties, and testing requirements.

Grades covered by this specification are A25 ,A ,B (and the following "X" Grades), X42, X46, X52, X56, X60, X65, X70, X80. The two digit number following the "X" indicates the Minimum Yield Strength (in 000's psi) of pipe produced to this grade.

API 5L X80 Pipe Properties

| X80 API5L | Comparison of steel grades | |

| EN10208-2 | L555MB | |

API 5L X80 Pipe Chemical Properties

API 5L X80 Chemical analysis -% by mass*

| Grades | Material number | C max | Si max | Mn. max | P max | S max | AL min | Mo max | Ni max | Nb max |

|---|---|---|---|---|---|---|---|---|---|---|

| X80 | 1.8978 | 0.08 | 0.26 | 1.75 | 0.011 | 0.0005 | 0.03 | 0.27 | 0.22 | 0.070 |

API 5L X80 Pipe Mechanical Propertities

| Grade | Permissible yield point ratio | Yield Strength MPa(min) | Tensile Strength MPa | Elongation % (min) |

|---|---|---|---|---|

| X80 | ≤ 0.90 | 555 | 625 - 700 | 20 |

Material Grades

| High Temperature Seamless Pipe | ASTM A106 Gr. B/C, API 5L Gr. B, ASTM A53 Gr. B |

|---|---|

| Heat Exchanger Seamless Tube | ASTM A179 |

| Low Temperature Seamless Pipe | ASTM A333 Gr. 3/6 |

| Low Temperature Seamless Tube | ASTM A334 Gr. 6 |

| High Yield Seamless Pipe | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80 PSL-1/PSL-2 |

| High Yield Seamless Pipe | ISO 3183 Gr.L245, L290, L320, L360, L390, L415, L450, L485 |

| Atmospheric & Low Temp EFW Pipes | ASTM A671 Gr. CC60/CC65/CC70 |

| High Pressure & Moderate Temp EFW Pipes | ASTM A672 Gr. B60/B65/B70/C55/C60/C65/C70 |

| High Yield ERW/SAW Pipe | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80 PSL-1/PSL-2 |

| High Yield ERW/SAW Pipe | ISO 3183 Gr.L245, L290, L320, L360, L390, L415, L450, L485 |

-

Seamless Line Pipe

API 5L X80 Pipe

Chemical Requirements, Percent (Product) Specification Grade C Max Mn Max P Max S Max Other API 5L PSL 1a Gr. A

Gr. B

X42

X45,X52,X56

X60e,X65e,X70e0.22

0.28

0.28

0.28

0.280.90

1.20

1.30

1.40

1.400.030

0.030

0.030

0.030

0.0300.030

0.030

0.030

0.030

0.030--

b,d

c,d

c,d

c,dAPI 5L PSL 2a Gr. B

X42

X46,X52,X56

X60e,X56e

X70e,X80e0.24

0.24

0.24

0.24

0.241.20

1.30

1.40

1.40

1.400.025

0.025

0.025

0.025

0.0250.015

0.015

0.015

0.015

0.015b,c

c,d

c,d

c,d

c,d

-

PSL 2 Specification

The API 5L specification establishes requirements for two product specification levels (PSL 1 and PSL 2) 1. The two PSL designations define different levels of standard technical requirements. The table presented here summarizes PSL 2:

Parameters PSL 2 Steel grades B - X120 Dimensions 114,3 - 2032,0 mm Pipe ends Plain (unless otherwise agreed) Welding process All, except laser Heat treatments (M,N or Q&T) For all grades from B through X120 Chemistry defined C/Si/Mn/P/S/V/Nb/Ti/CE2 Max % C in seamless 0,24% for N pipes, 0,18 for Q pipes, up to X65 Max % C in welded pipes 0,22% for grade BM to X56M, 0,12% for X60M to X80M Max % P 0,025% for grade B to X80M/Q Max % S 0,015% for grade B to X80M/Q Carbon equivalent The maximum established for each grade Maximum yield strength The maximum established for each grade Maximum tensile stress The maximum established for each grade Charpy impact test Required for all grades at a min. of 0°C/32°F Repair of body by welding Not allowed Repair of weld by welding Not allowed Certification Mandatory as per 10.1.3 The above table is extracted from API Specification 5L, 45th Edition.

1 Our stocks are all specified in (the higher) PSL 2 grade, killed and made according to fine grain practice.

2 Carbon mass fraction (of product analysis) equal or less than 0,12%, the carbon equivalent shall be reported as CEpcm.Note: Annexes with specific manufacturing or service requirements

- Annex B: Qualified manufacturing procedure for PSL 2 pipe

- Annex H: Sour services PSL 2 pipe

- Annex J: Offshore services PSL 2 pipe

-

API 5L X80 Pipe Useful Info

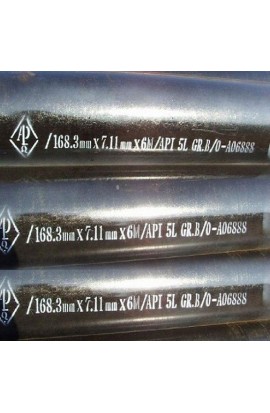

How to identify API 5L X80 Pipe

Threading on API 5L X80 Pipe can be identified either by stamping or stenciling the pipe adjacent to the threaded ends, which are at the manufacturer’s option. It should be with the manufacturer’s name or mark, “Spec 58” (to indicate the applicable threading specification), the specified outside diameter of the pipe, and the letters “LP” (to indicate the type of thread). The thread marking may be applied to products that do or do not bear the API monogram. For example, size 2 3/8- threaded-end pipe may be marked as follows, using the value that is appropriate for the pipe out- side diameter specified on the purchase order

API 5L X80 Pipe Permissable Variations

Wall Thickness : the minimum wall thickness at any point or end on API 5L pipes and tubes shall not be greater than 12.5% under the nominal thickness specified.

Inner Diameter: For pipe ordered in inside diameter, the inside diameter shall not vary more than ñ 1% from the required/specified inside diameter.API 5L X80 Pipe Inspection Certification

The use of the letters ‘Spec SB’ as provided in 10.8 shall constitute a certification by the manufacturer for API 5L X80 Pipe PSL1 Carbon Steel Seamless Pipes that the threads so marked comply with the requirements in API Standard S8 but should not be constructed by the purchaser as a representation that the product so marked is, in its entirety, in accordance with any API specification. Manufacturers who use the letters “Spec SB” for thread identification are required to have access to properly certified API master pipe gauges.

Material Certification

Pipes and Tubes manufactured as per API 5L X80 Pipe PSL1 are certified with En 10204 Type 3.1/3.2. IBR,NACE,HIC,IGC,IMPACT are adhered as supplementary testing requirements.

API 5L X80 Pipe Mechanical Requirements

a.) For intermediate grades, the differencec between the specified minimum tensile strength and the specified minimum yield strength for the pipe body shall be as given in the table for the next higher grade.

b.) For Intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determines for the pipe body using footnote

c.) The specified minimum elongation, Af, expressed in percent and rounded to the nearest percent.API 5L X80 Pipe Chemical Requirements

For each reduction of 0.0 I% below the specified maximum carbon content, an increase of 0.05% above the specified maximum manganese content is permissible, up to a maximum of 1.50% for Grades API 5L X42, X46 & X52, up to a maximum of 1.65% for grades higher than X52 butt less than X70 like API 5L X56, X60 & X65 up to 2.00% for Grades X70 and higher. Following are the additional restrictions applicable for API 5L pipes and tubes.

1.) The sum of columbium Niobium and vanadium contents shall not exceed 0.03%, except that, by agreement between the purchaser and the manufacturer, an alternative maximum may be established.

2.) Columbium niobium & vanadium, or combinations thereof may be used at the discretion of the manufacturer.

3.) The sum of the columbium 1 niobium, vanadium, and titanium contents shall not exceed 0.15%.

4) The sum of the columbium, Niobium and vanadium contents shall not exceed 0.06% except that, by agreement between the purchaser and the manufacturer, an alternative maximum may be established.

5.) Further chemical compositions may be furnished by agreement between purchaser and manufacturer, providing that the limits are footnoted and the tabular Limits for phosphorus and sulfur are met.API 5L X80 Pipe Carbon Equivalent

For API 5L X80 Pipe PSL2 pipes and tubes, carbon equivalent (CE) calculations shall be based on the product analyses and shall be calculated as follows. All carbon equivalent results shall be reported:

a. When the carbon content is less than or equal to 0.12%, the carbon equivalent shall be calculated using the following formula for CE(Pcm) [see Note I]:

CE(Pcm) = C+ Si/30+Mn/20+ Cu/20+ Ni/60 + Cr/20 + Mo/15 + V/10 + 5B

If the heat analysis indicates a boron content less than 0.00I%, then the product analysis need not include boron, and the boron content can be considered as zero for the CE(Pcm) calculation.

b. When the carbon content is greater than 0.12%, the carbon equivalent shall be calculated using the following formula for CE(lIW) [see Note 2]:

CE(Pcm) = C + Mn/6 + (CR+MO+V)/5 +(NI+CU)/15API 5L X80 Pipe Color Identification

The manufacturer shall apply a 2 in. (50 mm) daub of paint of the appropriate color on the inside surface at one end of each length of API 5L X80 Pipe / PSL1 Pipes.

-

Stock List

API-5L-X65 PSL-1/PSL-2 Seamless, ERW, HFW, LSAW, DSAW, HSAW/SSAW (Spiral Welded) Line Pipe

API-5L Grade-B, X-42, X-46, X-52, X-56, X-60, X-65, X-70, X-80 PSL1 PSL2 Line Pipe

API 5L Grade B PSL1 Line Pipes - Available ex-stock

API 5L Grade B PSL2 Line Pipes - Available ex-stock

API 5L Grade B PSL1 Sour Service Line Pipes - Available ex-stock

API 5L Grade B PSL2 Sour Service Line Pipes - Available ex-stock

API 5L Grade B PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L Grade B PSL2 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X42 PSL1 Line Pipes - Available ex-stock

API 5L X42 PSL2 Line Pipes - Available ex-stock

API 5L X42 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X42 PSL2 Sour Service Line Pipes - Available ex-stock

API 5L X42 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X42 PSL2 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X46 PSL1 Line Pipes - Available ex-stock contact us for stock availability

API 5L X46 PSL2 Line Pipes - Available ex-stock

API 5L X46 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X46 PSL2 Sour Service Line Pipes - Available ex-stock

API 5L X46 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X46 PSL2 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X52 PSL1 Line Pipes - Available ex-stock

API 5L X52 PSL2 Line Pipes - Available ex-stock

API 5L X52 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X52 PSL2 Sour Service Line Pipes - Available ex-stock

API 5L X52 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X52 PSL2 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X56 PSL1 Line Pipes - Available ex-stock

API 5L X56 PSL2 Line Pipes - Available ex-stock

API 5L X56 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X56 PSL2 Sour Service Line Pipes - Available ex-stock

API 5L X56 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X56 PSL2 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X60 PSL1 Line Pipes - Available ex-stock

API 5L X60 PSL2 Line Pipes - Available ex-stock

API 5L X60 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X60 PSL2 Sour Service Line Pipes - Available ex-stock

API 5L X60 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X60 PSL2 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X65 PSL1 Line Pipes - Available ex-stock

API 5L X65 PSL2 Line Pipes - Available ex-stock

API 5L X65 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X65 PSL2 Sour Service Line Pipes - Available ex-stock

API 5L X65 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X65 PSL2 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X70 PSL1 Line Pipes - Available ex-stock

API 5L X70 PSL2 Line Pipes - Available ex-stock

API 5L X70 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X70 PSL2 Sour Service Line Pipes - Available ex-stock

API 5L X70 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X70 PSL2 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X80 PSL1 Line Pipes - Available ex-stock

API 5L X80 PSL2 Line Pipes - Available ex-stock

API 5L X80 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X80 PSL2 Sour Service Line Pipes - Available ex-stock

API 5L X80 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X80 PSL2 NACE MR-0175 Line Pipes - Available ex-stockHigh Yield Seamless Pipes

- API 5L X52/L360 PSL 2

- EN 10225 G15

- Norsok M-120 Y22High Yield Seamless Pipes

- API 5L X65/L450 PSL 2High Yield SAW Welded Pipes

- API 5L X52/L360 PSL 2

- API 5L X56/L390 PSL 2

- API 5L X65/450 PSL 2High Yield Offshore Plates

- API 2W Gr 50/Gr 60

- API 2H Gr 50

- EN 10225 S355 G10+M

- EN 10225 S420 G2+M

- EN 10225 S460 G2+M

- Norsok M-120 Y20/Y30/Y40High Yield Offshore Sections

- EN 10225 S355 G11+M

- EN 10025 S355ML

- Norsok M-120 Y26We deal in all this grades api5lx65, api 5l x65, API 5L GR.B PSL 1, API 5L X 42 PSL 1, API 5L X 46 PSL 1, API 5L X 52 PSL 1, API 5L X 56 PSL 1, API 5L X 60 PSL 1, API 5L X 65 PSL 1, API 5L X 70 PSL 1, API 5L GR.B PSL 2, API 5L X42 PSL 2, API 5L X46 PSL 2, API 5L X52 PSL 2, API 5L X56 PSL 2, API 5L X60 PSL 2, API 5L X65 PSL 2, API 5L X70 PSL 2We mainly stock the Pipes of following make :

Pipes Make: ISMT, MSL, JSL, TATA, BHUSHAN, JINDAL, SUMITOMO, TENARIS, ARCELOR MITTAL

x42 x46 x52 x56 x60 x65 x70 x80 x100 Sumitomo Metal - Japan

x42 x46 x52 x56 x60 x65 x70 x80 x100 Nippon Steel - Japan

x42 x46 x52 x56 x60 x65 x70 x80 x100 JFE Steel - Japan

x42 x46 x52 x56 x60 x65 x70 x80 x100 Kawasaki Steel - Japan

x42 x46 x52 x56 x60 x65 x70 x80 x100 Vallourec & Mannesmann - France

x42 x46 x52 x56 x60 x65 x70 x80 x100 Vallourec & Mannesmann - Germany

x42 x46 x52 x56 x60 x65 x70 x80 x100 Vallourec & Mannesmann - Brazil

x42 x46 x52 x56 x60 x65 x70 x80 x100 Salzgitter Mannesmann - Germany

x42 x46 x52 x56 x60 x65 x70 x80 x100 Arcelor Mittal Steel - Romania

x42 x46 x52 x56 x60 x65 x70 x80 x100 Arcelor Mittal Steel - Czech Republic

x42 x46 x52 x56 x60 x65 x70 x80 x100 Tenaris Dalmine - Spain

x42 x46 x52 x56 x60 x65 x70 x80 x100 Tenaris Silcotub - Romania

x42 x46 x52 x56 x60 x65 x70 x80 x100 Tenaris Siderca - Argentina

x42 x46 x52 x56 x60 x65 x70 x80 x100 Tenaris Tamsa - Mexico

x42 x46 x52 x56 x60 x65 x70 x80 x100 Tenaris NKK - Japan

x42 x46 x52 x56 x60 x65 x70 x80 x100 Volzhski - Russia

x42 x46 x52 x56 x60 x65 x70 x80 x100 Nizhnedneprovsky - Ukraine

x42 x46 x52 x56 x60 x65 x70 x80 x100 USS - USA

x42 x46 x52 x56 x60 x65 x70 x80 x100 Welspun - India

x42 x46 x52 x56 x60 x65 x70 x80 x100 Jindal Saw - India

x42 x46 x52 x56 x60 x65 x70 x80 x100 Indian Seamless - India

x42 x46 x52 x56 x60 x65 x70 x80 x100 Maharashtra Seamless Limited/ MSL- India (specialized in Manufacturing Seamless & ERW Line Pipes)

API 5L X80 Pipe Marking & Packaging

- Each API 5L X80 Pipe is marked with tube type, heat number, steel grade and size. Other markings, such as stamping, can be made on request.

- Painted Stenciled or Die Stamped

- Manufacturer's name or mark, api5l, Spec 5L, gr.b pipe, size, weight per foot, grade, process of manufacture, type of steel, length (NPS 4 and larger only). Test pressure when hogher than tabulated (NPS 2 and larger only). Heat treat symbols, as applicable - HN, HS, HA or HQ.

|

API 5L X80 Pipe packed in MD Exports LLP's stockyard (api5l-b) |

API 5L X80 Pipe packed for shipping (api5l grade b) |

SEA WORTHY PACKING: Hexagonal shaper bundled with strong steel strips. Plastic caps on both of the pipes. Other types of packing can be made according to the customer's requirements

As we are supplying api5l grb & API 5L X80 Pipe globally so we have our dedicated sales representatives & technical consultant engineer in Nigeria, South Africa, Australia, Italy, Iran, Iraq, Israel, Turkey, Spain, Indonesia, Saudi Arabia, Oman, Qatar, Kuwait, South Korea, Canada, Japan, Yemen, Netherlands, Singapore, Malaysia who can provide you detailed information about API 5L X80 Pipe & comparison with other grades which will help you to choose the right steel pipe for your project at lowest price available in the market. For free consultancy or technical query you can send mail to our technical experts.

API 5L X80 Pipe related line pipe materials stock:

We also stock other steel line pipe grades, please check the list of steel grades below:

India's Largest Stockist & Dealers of api5l gr b & api5l seamless pipe

Looking for API 5L X80 Pipe? First time in India selling steel Pipe & API 5L X80 Pipe online at lowest price with all shipping documents, supplying API 5L X80 Pipe with mill certificate, all size & grades seamless pipes is in ready stock, Hot offer - flat 6% off on API 5L X80 Pipe

Reviews

No customer comments for the moment.

Summary

- Product Name:API 5L X80 Pipe suppliers

- Price: $ 2.00

- Product Width: 0.00 cm

- Product Height: 0.00 cm

- Product Depth: 0.00 cm

- Product Weight: 0.00 kg

- Description: Other Trade name: API 5L Seamless Line Pipe, X52 Grade Steel Pipe, API 5L X52, 5L X56, 5L X60, 5L X65, 5L X70 X80 PSL1/ PSL2 Pipe, API 5L Line Pipe, api 5lx pipe, api 5l grade b Calculate Your Pipe Weight (It will open in new window)